CLASSIFICATION

» "O" rings

» Rectangular-section rings

» "U"-shaped gaskets

» Elbows and sleeves

» Friction plates

» Rubber rings for conveyor metal rollers

» Rubber scrapers for conveyor belts

» Separator curtains

» Rubber sealing cords

» Bearing pads

» Snow scrapers

» "U"-shaped cuffs

» Rubber flanges

Mark: Artego

- Description

- Reviews (0)

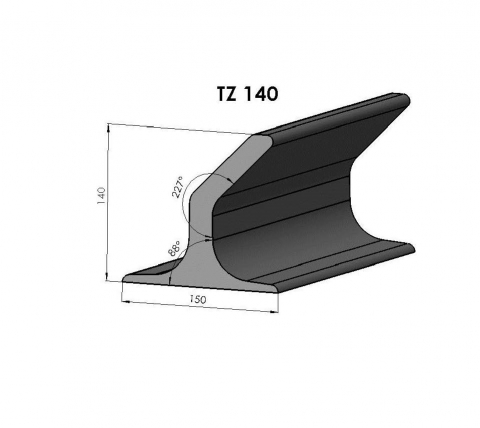

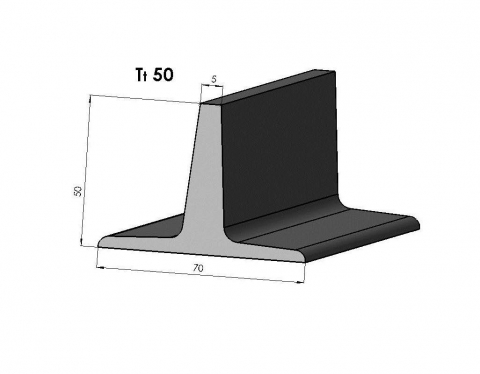

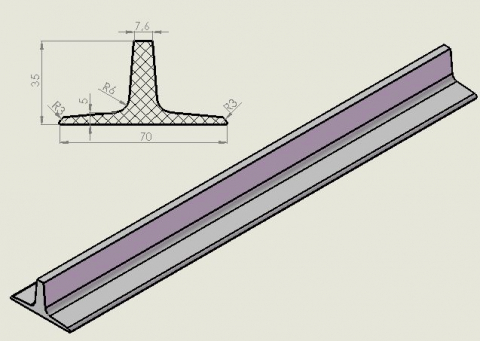

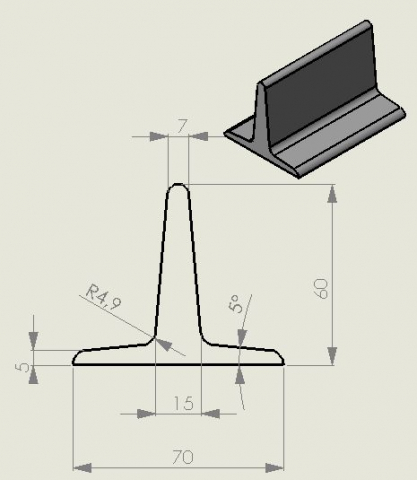

Rubber Gaskets are divided into two main categories based on production method and feasibility: pressed gaskets and profiled gaskets. The difference between the two types lies in their manufacturing process: pressed gaskets are produced in molds through heat pressing, while profiled gaskets are made by extrusion.

Extrusion is carried out using a wide range of extrusion profiles, and their vulcanization takes place in autoclaves with controlled temperature throughout the technological process (large ovens).

S.C. ARTEGO S.A. offers a wide range of gaskets:

– simple, without reinforcements;

– with textile inserts for flexibility;

– with metal reinforcements for rigidity;

– made from different compounds: SBR, NR, NBR, EPDM, depending on customer requirements.

CLASSIFICATION

» "O" rings

» Rectangular-section rings

» "U"-shaped gaskets

» Elbows and sleeves

» Friction plates

» Rubber rings for conveyor metal rollers

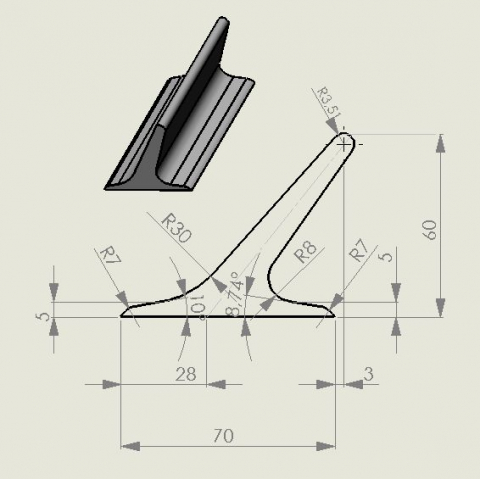

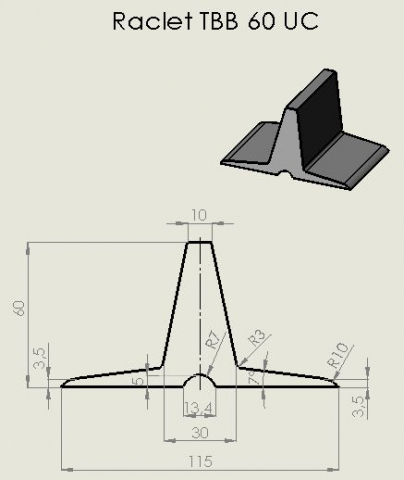

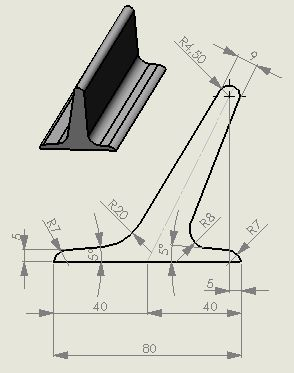

» Rubber scrapers for conveyor belts

» Separator curtains

» Rubber sealing cords

» Bearing pads

» Snow scrapers

» "U"-shaped cuffs

» Rubber flanges

For more commercial information, contact us at online@artego.ro

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [0] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [0]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-488877.jpg)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [1] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [1]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-595150.jpg)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [2] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [2]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-441008.jpg)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [3] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [3]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-805263.webp)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [4] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [4]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-598341.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [5] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [5]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-173696.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [6] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [6]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-362837.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [7] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [7]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-078352.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [8] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [8]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-124121.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [9] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [9]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/medium/garnituri-din-cauciuc-presate-si-profilate-869416.jpg)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [1] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [1]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-488877.jpg)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [2] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [2]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-595150.jpg)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [3] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [3]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-441008.jpg)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [4] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [4]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-805263.webp)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [5] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [5]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-598341.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [6] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [6]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-173696.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [7] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [7]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-362837.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [8] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [8]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-078352.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [9] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [9]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-124121.png)

![High Quality Rubber Gaskets – Guaranteed Sealing and Durability [10] High Quality Rubber Gaskets – Guaranteed Sealing and Durability [10]](https://gomagcdn.ro/domains2/magazin.artego.ro/files/product/large/garnituri-din-cauciuc-presate-si-profilate-869416.jpg)